Cardboard Model with laser Engraving & Cutting | GCC: Laser Machines Leader Since 1989

-

X252 80-100W CO2 Laser Cutter

X252 80-100W CO2 Laser Cutter -

S400 Dual Laser System Laser Engraver

S400 Dual Laser System Laser Engraver -

X380 80-100W CO2 Laser Cutter

X380 80-100W CO2 Laser Cutter -

Spirit GLS Hybrid CO2 Fiber Laser Engraver

Spirit GLS Hybrid CO2 Fiber Laser Engraver -

🆕 X500III Pro 100-150W CO2 Laser Cutter

🆕 X500III Pro 100-150W CO2 Laser Cutter -

Spirit LS 12-100W CO2 Laser Engraver

Spirit LS 12-100W CO2 Laser Engraver -

C180II 12-40W CO2 Desktop Laser Engraver

C180II 12-40W CO2 Desktop Laser Engraver -

T500 60-200W CO2 Laser Cutter

T500 60-200W CO2 Laser Cutter -

Spirit 12-100W CO2 Laser Engraver

Spirit 12-100W CO2 Laser Engraver -

🆕 E200 40W CO2 Desktop Laser Engraver

🆕 E200 40W CO2 Desktop Laser Engraver -

S290LS 20-60W Fiber Laser Engraver

S290LS 20-60W Fiber Laser Engraver -

Mercury III 12-80W CO2 Laser Engraver

Mercury III 12-80W CO2 Laser Engraver -

MG380Hybrid 12-100W CO2 Laser Engraver

MG380Hybrid 12-100W CO2 Laser Engraver -

MG380Hybrid 12-100W CO2 Laser Cutter

MG380Hybrid 12-100W CO2 Laser Cutter

Scissors and utility knives are commonly used tools for cutting in general. For common materials such as paper and plastic sheets, these tools make cutting easy. However, when it comes to thicker objects that require fast cutting, using these tools may not be convenient. Is there any method available to quickly cut your objects?

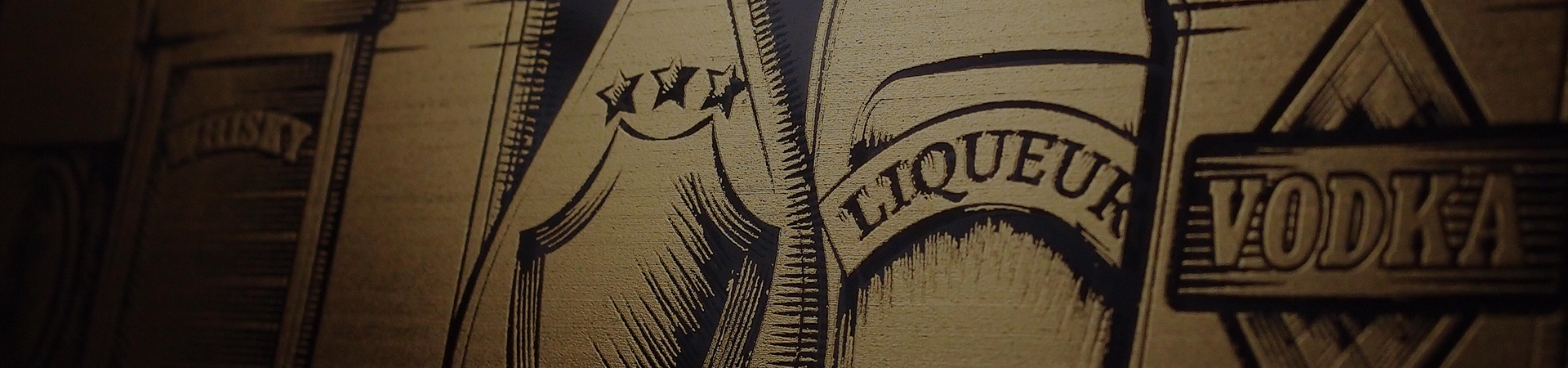

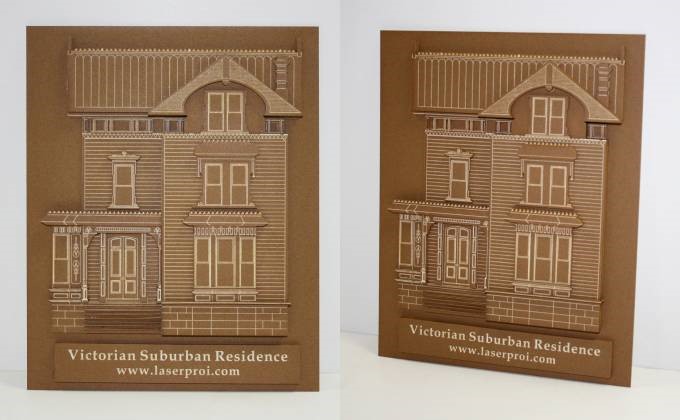

In this showcase, the GCC LaserPro Application Lab demonstrates the use of the Laser Engraver series to cut thick cardboard. Not only does it save time compared to manual cutting, but it also provides a smoother cutting result. Additionally, it allows for laser engraving on the surface of the thick cardboard, enhancing the value of the product.

The lab obtained 1.2 mm thick cardboard and utilized laser engraving and cutting techniques to create 3D models. The cutting edges are smooth and the process is fast, while the engraved part achieves precise and intricate effects. Once the cut objects are assembled, they become high-value products. You can purchase rigid cardboard at local stationery stores and join forces with the GCC LaserPro Application Lab to create this sample.

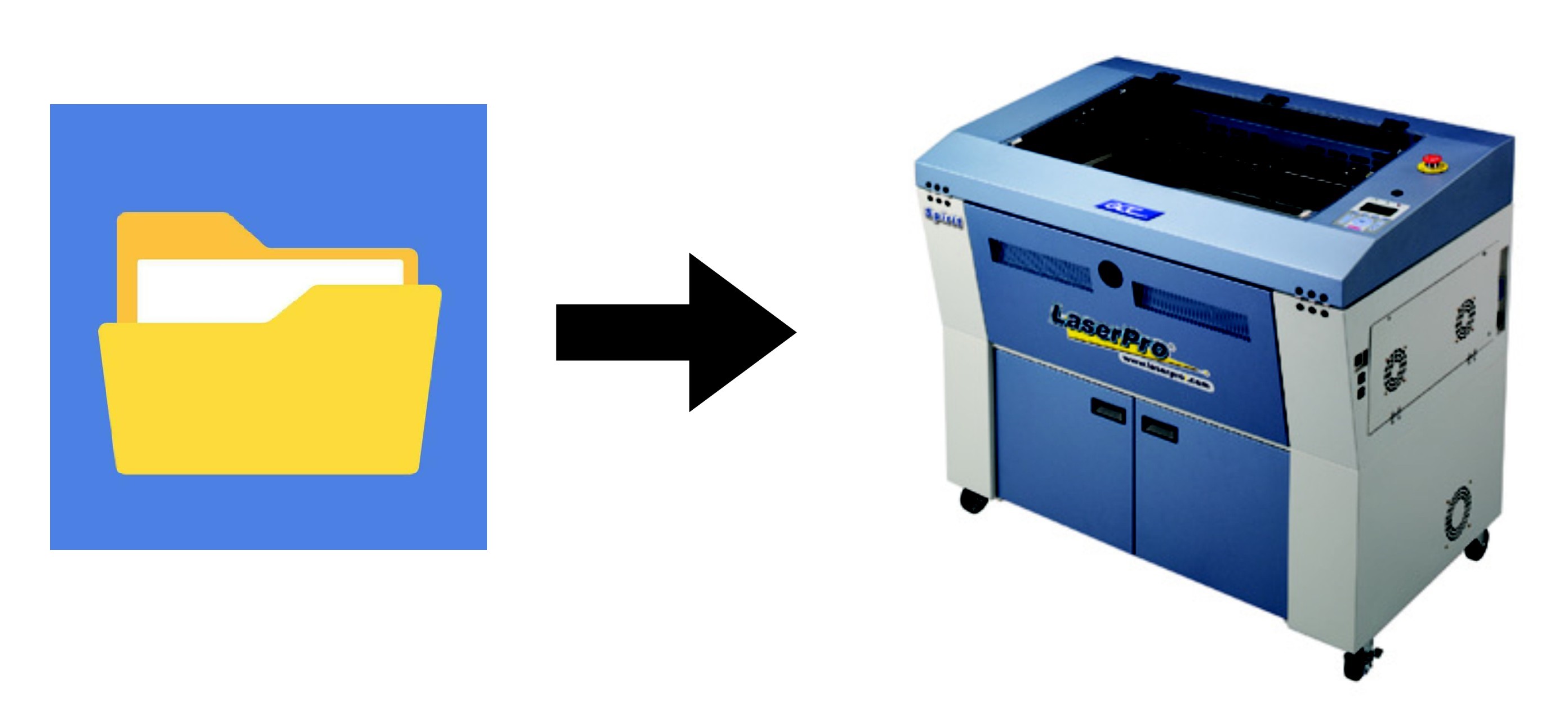

Step 1. After downloading the file, send the graphics to the laser engraving machine and set the appropriate parameters based on your machine's wattage.

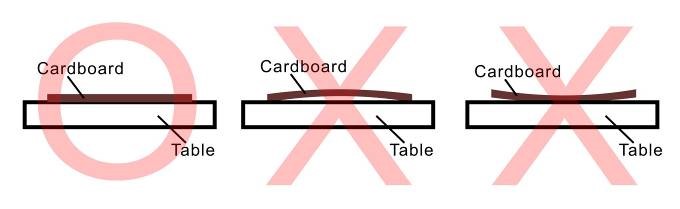

Step 2. Place the cardboard flat on the machine platform, ensuring its smoothness, and prepare for laser engraving and cutting.

Step 3. Press Start to begin the processing.

Step 4. Assemble the cut objects; you can use a quick-drying glue stick to glue them together.

Sample:

Reference Parameters

| Spirit 60W | |||||

| Speed | Power | dpi | ppi | Mode | |

| Engraving | 80 % | 40 % | 500 | 400 | Manual Color Fill |

| Cutting | 10 % | 100 % | 500 | 400 | |

Black-Cutting Parameter

Red-Engrave Parameter

Tips:

•Prior to cutting, ensure the cardboard is flat to avoid focus issues that may affect the throughput quality.

•Pay attention to the sequence of laser engraving and cutting to maintain the integrity of the sample.

•Use an appropriate amount of glue during bonding to avoid damaging the surface of the sample.

•Different cardboard surfaces may have slight variations, so adjust the parameters accordingly during engraving.